Markets

YOGURT & DESSERTS

TRADITIONAL YOGURT (WITH MILK SKIN)

CREAMS & SPREADABLE CHEESE

BUTTER & MARGARINE

TOMATO PASTE, SAUCES & DIPS

FRUIT & VEGETABLE PUREE

NUT-BASED SPREADS

JAM, MARMALADE & JELLY

PROCESSED MEAT

WET PET FOOD

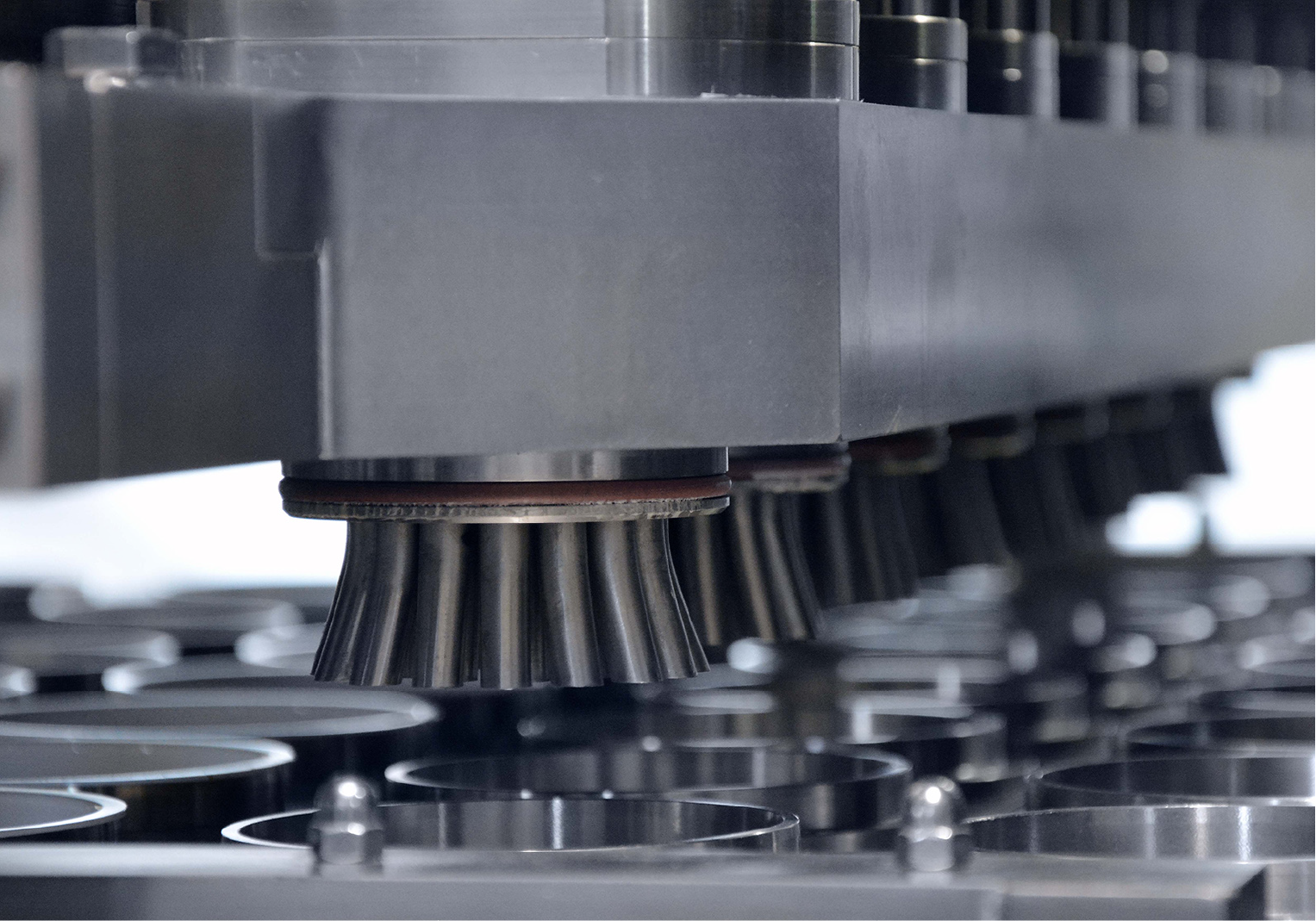

Filling Units

With Alfa Machine’s long extensive experience across the food industry, we have developed many innovative and efficient filling solutions. Our customized solutions fill products from warm milk for pot set yogurt to viscous sauces and processed meat, with or without particulates whilst ensuring high filling accuracy and providing you the flexibility to process several products on the same machine. Alfa Machine’s technical expertise guarantees both the quality of the product and the integrity of the packaging, even when filling products with high temperatures.

Key Features:

-

Filling nozzles appropriate for any liquid to viscous product with or without soft particulates up to Ø12mm.

-

Thick product handling for accurate dosing (i.e. mayonnaise, margarine, processed meat).

-

Cold or hot (up to 93°C) filling process.

-

Drip-free filling process.

-

316L stainless steel construction.

-

Aseptic type dosing pistons.

-

Servo-piston driven operation of dosing pistons for optimum accuracy: ±1% on homogenous products.

-

Hygienic design of the filler in order to eliminate product residue accumulation, according to EU safety standards.

-

Fully CIP & SIP connectable.

Options:

-

Double jacket product hopper and heated filling head.

-

Agitator with stainless steel motor.

-

Mixed & multi product dosing.

-

Just-in-time fruit injection with dynamic in-line mixers.

-

Flowmeter, recommended for liquid products.

Newsletter subscription

Contact info

-

This email address is being protected from spambots. You need JavaScript enabled to view it.