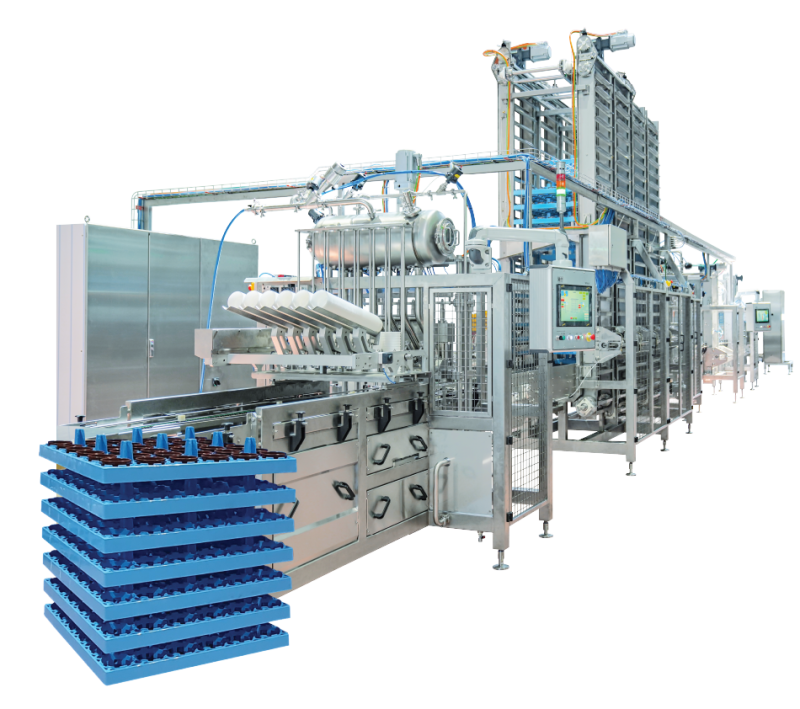

Traditional Yogurt Filling Line

TY15-L6

- Maximum output of 5,400 pcs/hour for containers with Ø110mm top rim, depending on project specifications.

- Servo-motor driven chain conveyors for highly smooth indexing.

- Automatic destacker and feeder for plastic cups.

- Remote diagnosis and maintenance provided by secure cloud technology.

- Maximum flexibility and user-friendly interface of HMI.

- Easy to operate and maintain.

Traditional yogurt (with milk skin) is a fresh dairy product and its filling process is labor intensive. The TY15-L6 line performs a fully automatic filling of traditional yogurt in pre-made plastic cups or clay pots, offering improved product quality and an outstanding increase of its shelf life over the manual process it replaces.

The advancing of the cups/pots throughout the line is performed in plastic trays (in a 6x6 arrangement) specially designed by Alfa Machine, which fit both types of containers and guarantee their safe and accurate indexing and the fast cooling of the product.

The smart design of this line is a true innovation by Alfa Machine, minimizing the footprint of the whole packing line making it just 15m long and under 2m wide. The complete line consists of the following equipment:

-

The Filling Machine is equipped with a volumetric high accuracy filling unit with aseptic type dosing pistons and nozzles with membranes specially designed for a drip-free and foam-free hot filling of pasteurized milk.

-

The clean room Tray Buffer Unit moves the trays with the filled pots slowly for about 30 minutes in order to cool down and allow the characteristic milk skin to form.

-

The Inoculation Unit consisting of a volumetric high accuracy filling unit with aseptic type dosing pistons and nozzles designed for the effective piercing of the yogurt live culture through the skin without damaging it.

-

The Tray Stacker smoothly places one plastic tray on top of the other in stacks of up to 12 trays. This procedure facilitates the trays’ transportation in and out of the incubation room.

Optional Equipment:

- Pulsed-UV light (LOG3) for containers sterilization.

- Stainless steel trolleys for manual transportation of the stacked trays.

- Tray De-stacker Unit for separating the trays after the incubation room.

- Container Extraction Unit to discharge the containers on a flat conveyor belt to be sealed.