"High-end technology designed for your packaging needs"

After 40 years of continuous effort Alfa Machine is rightly considered a leading company in the field of tailor-made packaging machinery. Our best guide for the future is our past, shaped by Alfa Machine's innovative spirit, its vast experience in machine manufacturing and its personalised after-sales support.

FRS-L 25/40

FORM-FILL-SEAL FOR DAIRY

- Ultra-Clean hygienic level

- Integrated IML system

- Production capacity up to 31,000 cups/hour

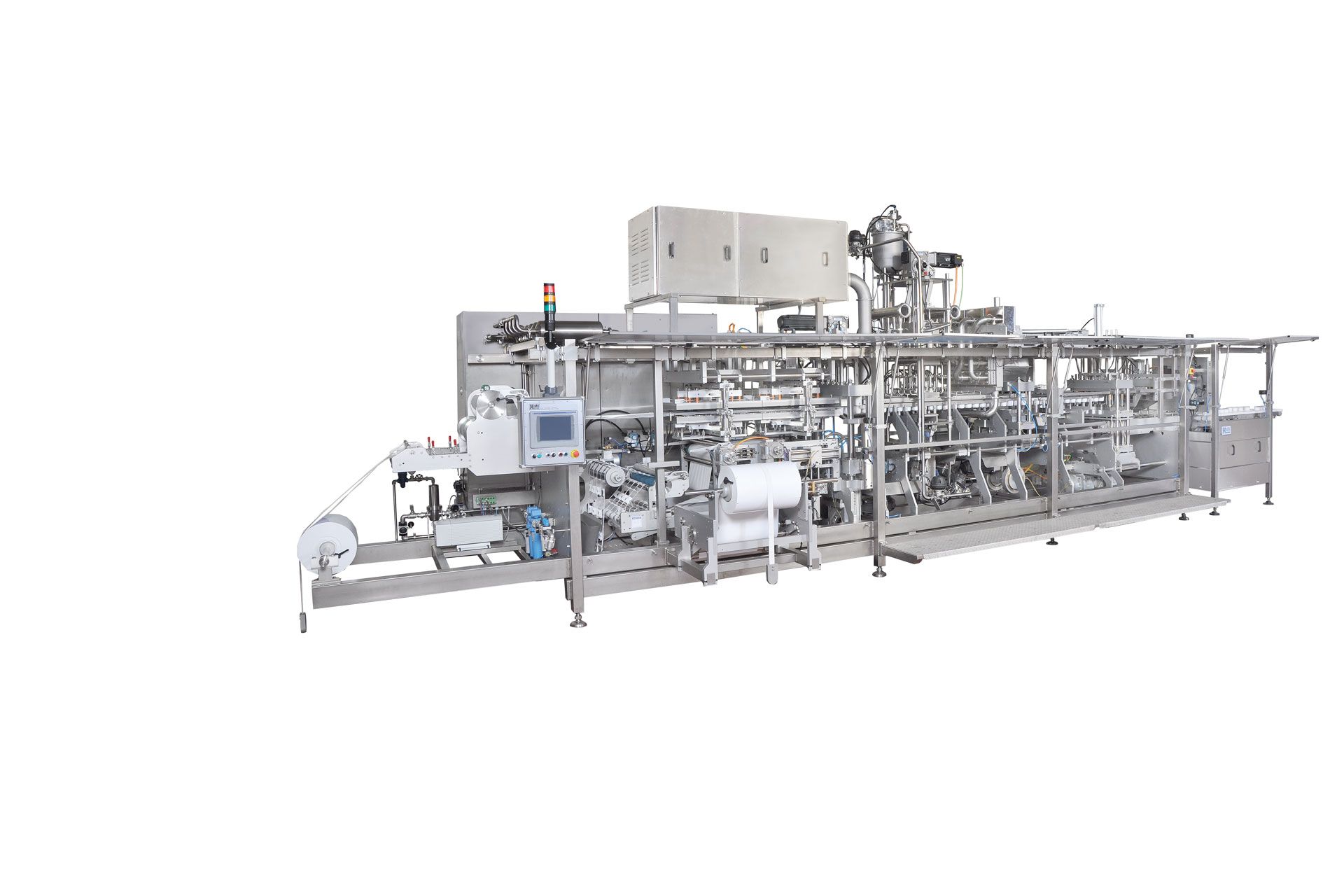

FCM30-L4/ FCM30-L6/ FCM30-L8/ FCM30-L10

LINEAR FILL-SEAL

- Pulsed-UV technology for cups and lids

- Inert gas flushing before the sealing

- Production capacity up to 7,200 / 10,800 / 14,500 / 18,000 cups/hour

FM30-R1/R2/R3

ROTARY FILL-SEAL

- Laminar flow hygienic level

- Inert gas flushing before the sealing

- Production capacity up to 1,800 / 3,600 / 5,400 cups/hour

FFS Advantages:

-

Multipack without overwrap

-

FFS pots cost 60% less expensive than a preformed pot

(lid also less expensive for a FFS cup or tub) -

Better hygienic control

-

Tailor-made design of cup or tub

-

Personalized after-sales support

-

Improved appearance with flexibility on paper label printing

-

One operator runs the machine

FS Advantages:

-

Wide variety of cup sizes - optimal flexibility

-

Convenient for batch production and private label products

-

Lower cost of investment compared with an FFS packaging machine

-

Compact design with smaller size

-

One operator can run the machine thanks to packaging materials magazines

-

Easier training of the operation staff