FRS-L 10/40 for

PET & PP Multipacks

PET & PP Multipacks

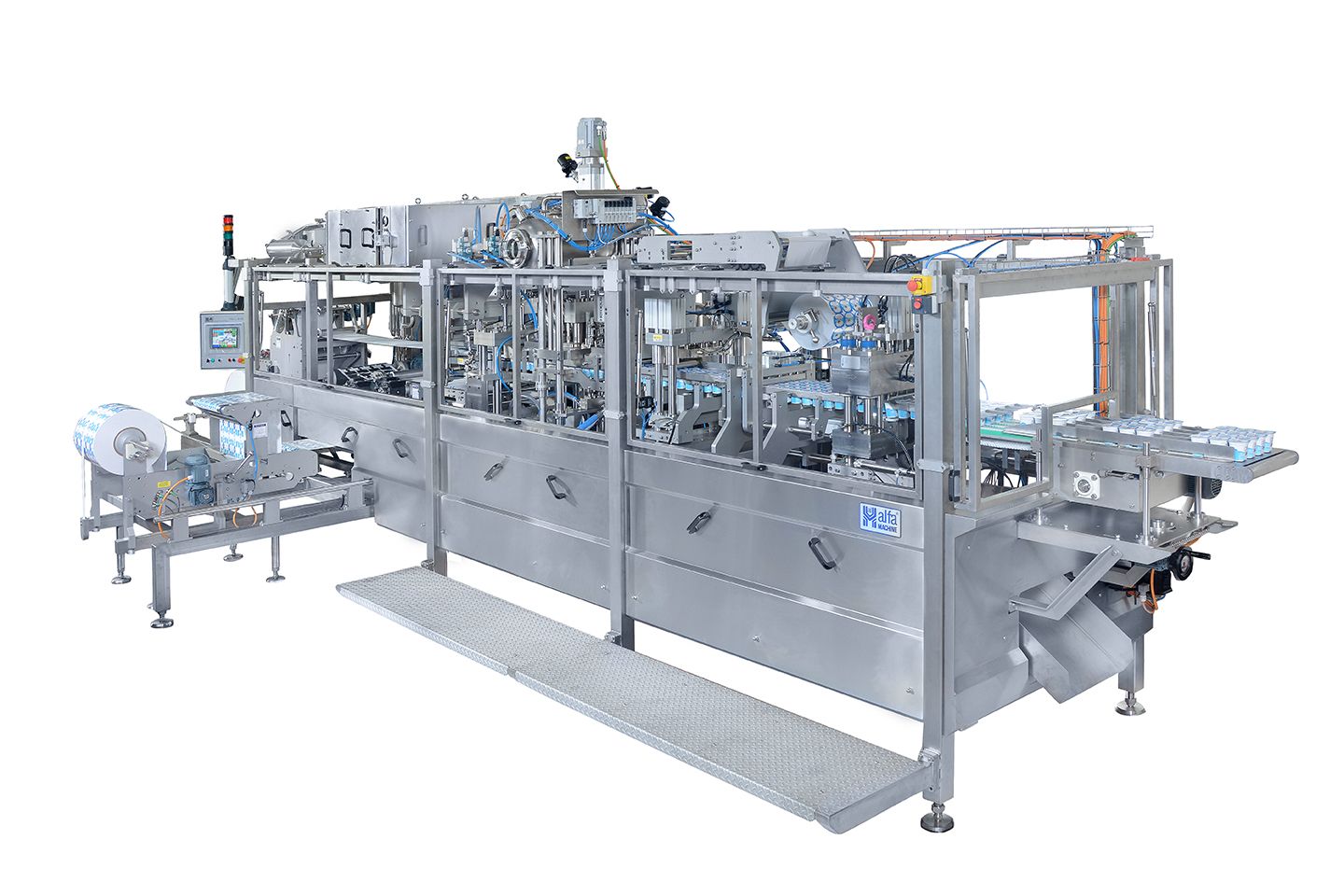

- Specially designed to operate with PET & PP material offering a completely recyclable and more cost-effective packaging solution compared to PS.

- Innovative pre-cut technology producing PET & PP multipacks which snap easily into individual cups.

- PP material is perfect for hot-filling applications (for example spread cheese, fruit puree and tomato plaste).

- The superior transparency of PET material makes it an optimal choice for applications requiring premium product visibility (for example yogurt with jam packaging).

- PET material is way less premeable to oxygen than PS, preserving food quality.

-

Appropriate for easy-snap PET Multipacks

-

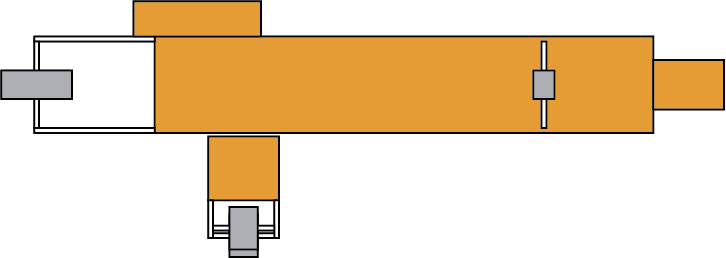

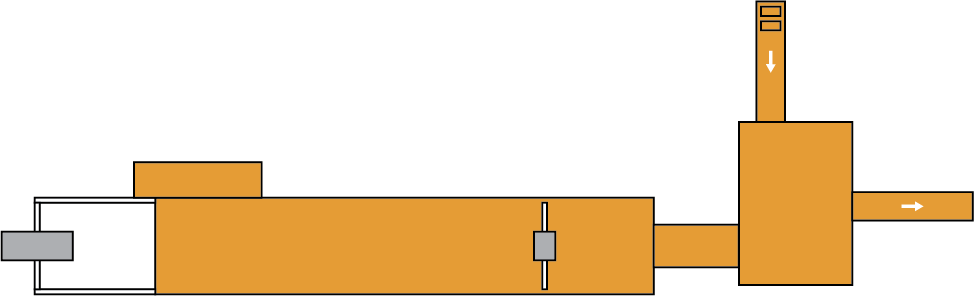

Forming Surface: 65 x 390 mm

-

Size of cups: 125g & 150g

-

Production Capacity (65 x 65mm): 10,800 cups per hour

-

In Mould Labeling (IML) system with full-body banderole paper label

-

Cutting format: 4-cup multipacks

-

Ultra-Clean hygienic version

-

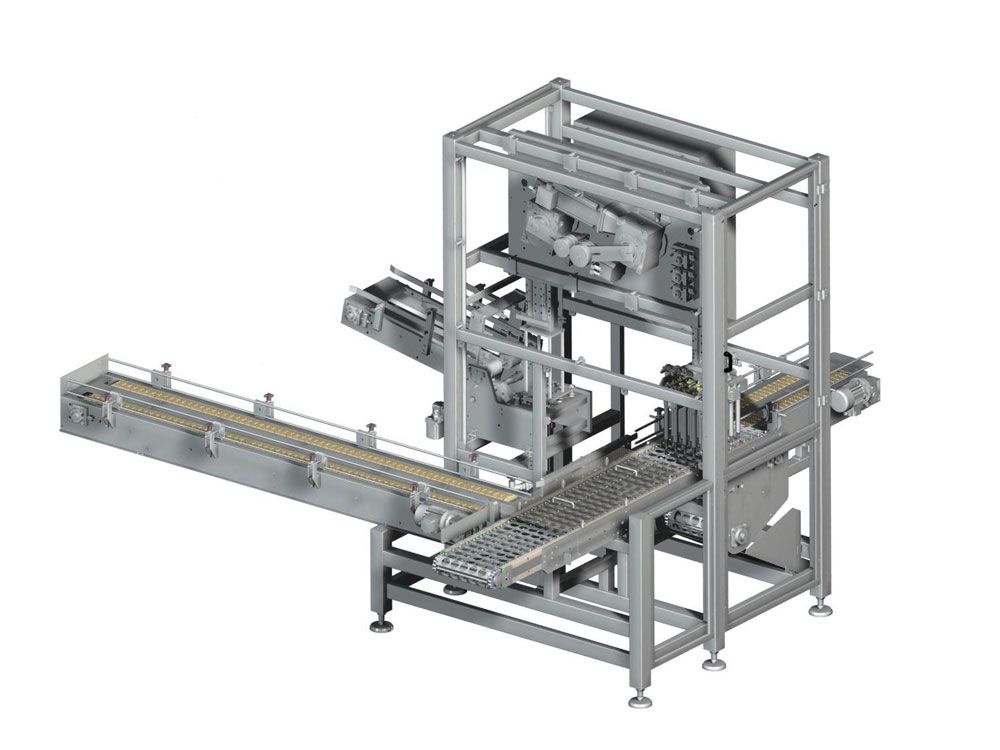

Servo-driven technology employed in every station of the machine (forming, filling, sealing, cutting, draw-off mechanism) for optimum accuracy & reliability

-

Easy to operate & maintain

- Advanced hygienic conditions with Ultra-Clean system (class IV according to VDMA standards):

- Class 100 clean air supply unit is consisting of:

- Coarse dust filter (G4),

- Fine dust filter (F9),

- HEPA (High Efficiency Particulate Air) filter H14.

- Class 100 clean air supply unit is consisting of:

- Clean-Air tunnel extended from the forming area up to the sealing station.

- Absolute control of packaging materials with Automatic Positioning system of the sealing and cutting station, individually, on every machine cycle accrding to the shrinkage of the base material.

- Vollumetric filling unit appropriate for any liquid & semi-viscous products:

- Servomotor driven operation for optimum dosing accuracy.

- Dosing range from 50 to 150ml.

- Manufactured by stainless steel 316L according to safety standards.

- Fully CIP and SIP connectable.

- Drip-free filling process due to nozzles with closing valves.

- UV curing system for the sterilization of the lid material.

- Maximum Flexibility and User Friendly interface of the PLC

- Remote diagnosis and maintenance provided by secure cloud technology.

- FRS-L 10/40 can be manufactured to produce PP Multipacks for hot-filling applications.

- Equipped with compact and reliable peripheral equipment, such as automatic case packer, the CIP skid, and the butter homogenizer.