FRS-L 16/26

FRS-L 25/26

- Inert gas flushing providing modified atmosphere packaging (less than 1% oxygen residue in the headspace of cups.

- Extended shelf life for sensitive products, like yogurt, desserts, or fresh juice.

- HEPA (High Efficiency Particulate Air) filter H14.

- Fully CIP and SIP connectable Filling unit.

- UV light for the decontamination of the lid material

- Forming Surface (mm): 180 x 260 & 250 x 260

- Production capacity (65 x 65 mm cups): 12,000 cups per hour

- Production capacity (Φ95mm cups) per hour: 6,000 - 9,000 cups per hour

- Production capacity (for mini single portions approx.): 28,000 – 35,000 portions per hour

- In Mould Labeling system with 3-sides label

- Multipacks of 4, 6 and 8 cups

- Ultra-Clean hygienic version

- High-end additional equipment

- Advanced hygienic conditions with Ultra-Clean system

- Class 100 clean air supply unit is consisting of:

- Coarse dust filter (G4)

- Fine dust filter (F9)

- HEPA (High Efficiency Particulate Air) filter H14

- Inert gas flushing providing modified atmosphere packaging

- Extended shelf life for sensitive products, like yogurt, desserts, or fresh juice

- In Mould Labelling (IML) system applied in all sides of vertical or conical cups

- Maximum Flexibility and User Friendly interface of the PLC

- Fully CIP and SIP connectable Filling unit

- Total control over packaging materials with Automatic Positioning Correction systems

- Servo-driven technology employed in every station (individual operation)

- Remote diagnosis application for remote intervention and repair

- PS, PET, PLA and all kinds of multilayer materials

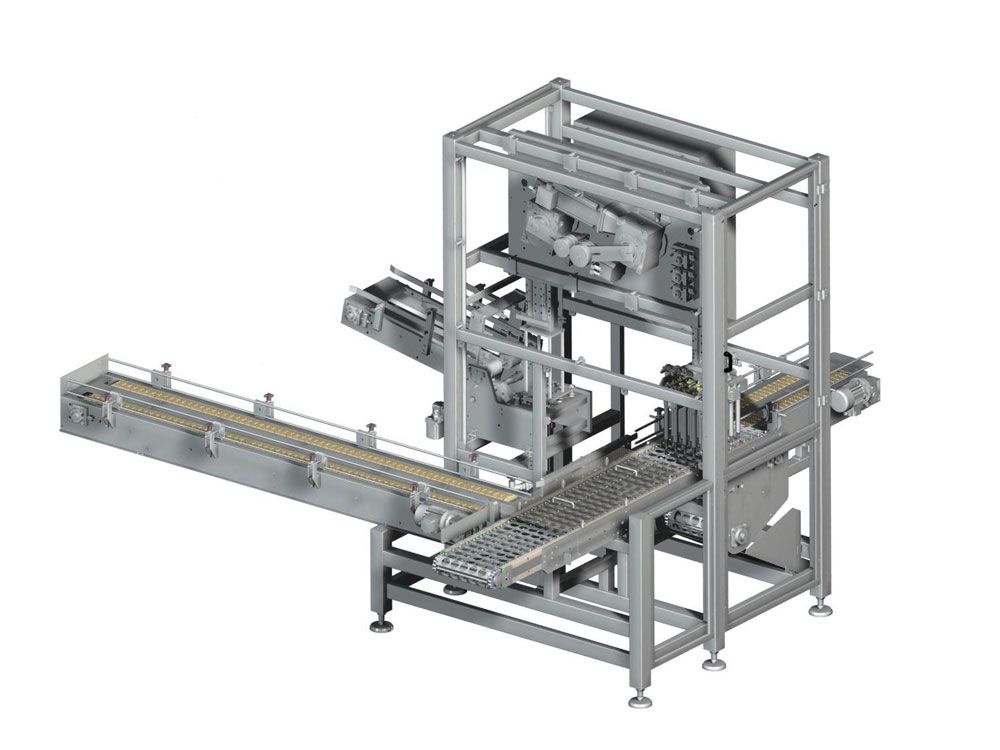

- Equipped with compact and reliable peripheral equipment, such as the automatic Tray/Case Packer system, the mobile CIP Feeder, and the mobile Butter Extruder mechanism.