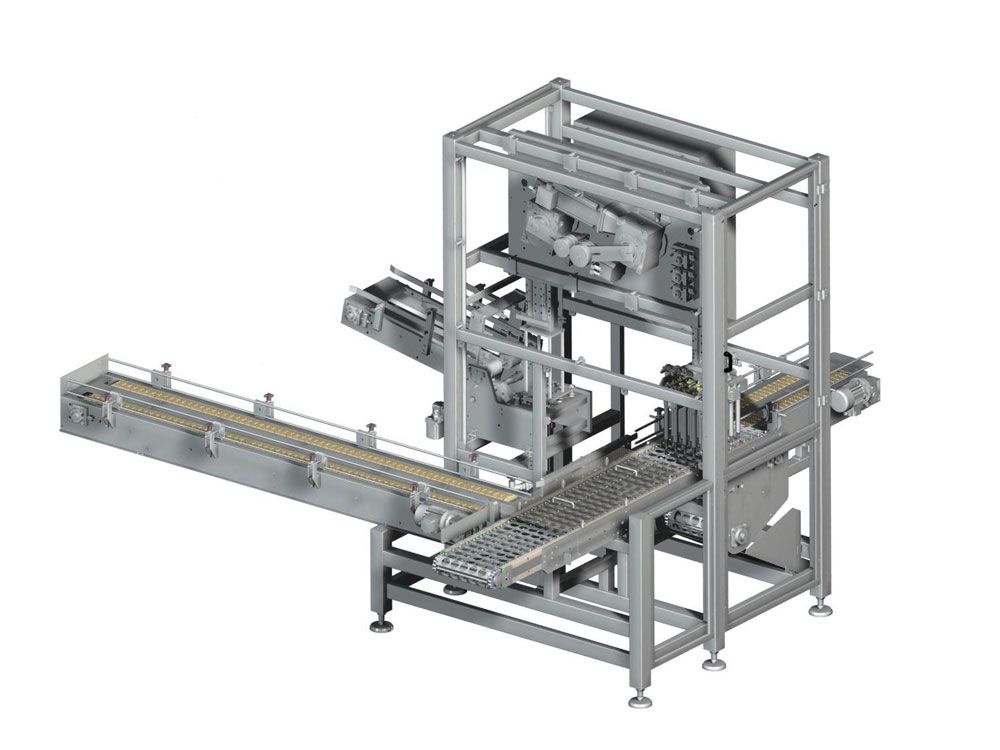

FRS 17/19

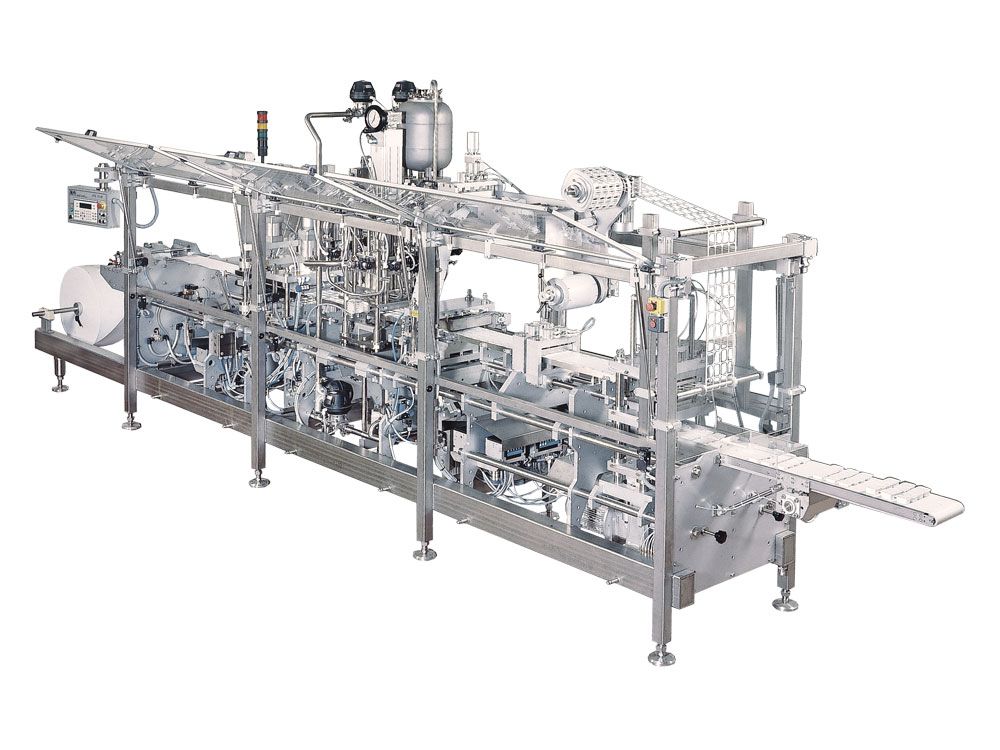

FRS 16/26

FRS 16/26

- Inert gas flushing providing modified atmosphere packaging (less than 1% oxygen residue in the headspace of cups.

- Extended shelf life for sensitive products, like yogurt, desserts, or fresh juice.

- HEPA (High Efficiency Particulate Air) filter H14.

- Fully CIP and SIP connectable Filling unit.

- UV light for the decontamination of the lid material

- Medium to large production volumes from 18,000 up to 30,000 mini portion cups per hour

- Available Forming Surface: 180 x 200 mm and 180 x 250 mm

- Ultra-Clean system (optional) for advanced hygienic conditions

- Superior quality and optimum operation accuracy with servo-driven technology employed in every station.

- Tailor-made shape of portion cup/container.

- The cutting profile can be in single or multipack format.

- Fully CIP connectable Filling station, manufactured by 316L stainless steel.

- Easy to operate and maintain

- Total control of packaging materials with automatic Positioning Correction systems on the sealing and cutting stations.

- Tele-diagnosis application with VPN internet connection for remote intervention and repair

- Suitable for any product such as jam, honey, butter, chocolate paste, sauces, water and many more

- Maximum Flexibility and User Friendly interface of the PLC

- The FRS 17/19 and the FRS 16/26 utilize PVC, PET, PS, PLA, and other multilayer packaging materials.